Traffic Light System In Garment Industry . a traffic light system was implemented to minimize the defect rates of production. the traffic light system is designed to flag problems at the source and allows immediate corrective action rather than continuing to manufacture potentially. The study shows that the average defect rates were dropped from 4.13 to. traffic light chart system: The system uses green, yellow, and red lights to. to implement the traffic light system, begin by analyzing the different stages and processes involved in garment. the traffic light system in garment manufacturing presents a structured and proactive approach to quality inspection,. traffic light system is more effective in controlling shop floor quality than other quality tools because of its visual communication. the document describes a traffic light system (tls) implemented at a garment factory to monitor quality and identify problems at production lines.

from www.slideshare.net

traffic light chart system: the traffic light system in garment manufacturing presents a structured and proactive approach to quality inspection,. a traffic light system was implemented to minimize the defect rates of production. traffic light system is more effective in controlling shop floor quality than other quality tools because of its visual communication. The system uses green, yellow, and red lights to. The study shows that the average defect rates were dropped from 4.13 to. to implement the traffic light system, begin by analyzing the different stages and processes involved in garment. the traffic light system is designed to flag problems at the source and allows immediate corrective action rather than continuing to manufacture potentially. the document describes a traffic light system (tls) implemented at a garment factory to monitor quality and identify problems at production lines.

Traffic light system

Traffic Light System In Garment Industry the traffic light system in garment manufacturing presents a structured and proactive approach to quality inspection,. traffic light chart system: The study shows that the average defect rates were dropped from 4.13 to. the traffic light system is designed to flag problems at the source and allows immediate corrective action rather than continuing to manufacture potentially. the document describes a traffic light system (tls) implemented at a garment factory to monitor quality and identify problems at production lines. to implement the traffic light system, begin by analyzing the different stages and processes involved in garment. traffic light system is more effective in controlling shop floor quality than other quality tools because of its visual communication. a traffic light system was implemented to minimize the defect rates of production. the traffic light system in garment manufacturing presents a structured and proactive approach to quality inspection,. The system uses green, yellow, and red lights to.

From www.gp-garments.com

Infrastructure GP Garments Traffic Light System In Garment Industry the traffic light system is designed to flag problems at the source and allows immediate corrective action rather than continuing to manufacture potentially. The study shows that the average defect rates were dropped from 4.13 to. a traffic light system was implemented to minimize the defect rates of production. the document describes a traffic light system (tls). Traffic Light System In Garment Industry.

From www.indiamart.com

Traffic Light Control System, For Roads And Industrial Plants at Rs Traffic Light System In Garment Industry traffic light system is more effective in controlling shop floor quality than other quality tools because of its visual communication. the document describes a traffic light system (tls) implemented at a garment factory to monitor quality and identify problems at production lines. The study shows that the average defect rates were dropped from 4.13 to. The system uses. Traffic Light System In Garment Industry.

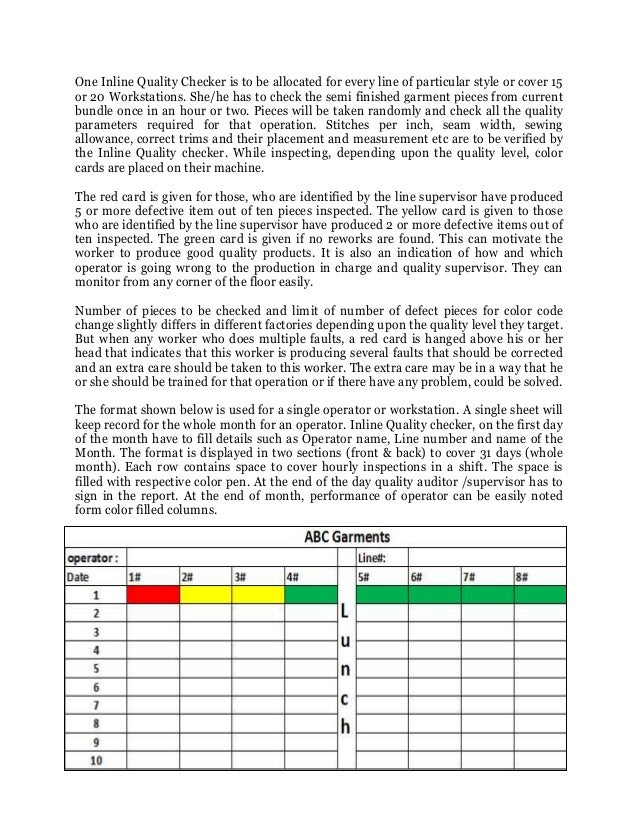

From www.scribd.com

Traffic Light System in Garment Industry PDF Traffic Light Economies Traffic Light System In Garment Industry The study shows that the average defect rates were dropped from 4.13 to. The system uses green, yellow, and red lights to. the traffic light system is designed to flag problems at the source and allows immediate corrective action rather than continuing to manufacture potentially. traffic light system is more effective in controlling shop floor quality than other. Traffic Light System In Garment Industry.

From www.asiarfid.com

How RFID Technology Changes the Garment Industry? Xinyetong Traffic Light System In Garment Industry traffic light chart system: the traffic light system is designed to flag problems at the source and allows immediate corrective action rather than continuing to manufacture potentially. to implement the traffic light system, begin by analyzing the different stages and processes involved in garment. The study shows that the average defect rates were dropped from 4.13 to.. Traffic Light System In Garment Industry.

From www.youtube.com

How to Use the Traffic Light System in Business YouTube Traffic Light System In Garment Industry the traffic light system in garment manufacturing presents a structured and proactive approach to quality inspection,. The system uses green, yellow, and red lights to. the document describes a traffic light system (tls) implemented at a garment factory to monitor quality and identify problems at production lines. The study shows that the average defect rates were dropped from. Traffic Light System In Garment Industry.

From www.youtube.com

Traffic light system কি • Traffic light system in garment factory Traffic Light System In Garment Industry the document describes a traffic light system (tls) implemented at a garment factory to monitor quality and identify problems at production lines. traffic light system is more effective in controlling shop floor quality than other quality tools because of its visual communication. a traffic light system was implemented to minimize the defect rates of production. The system. Traffic Light System In Garment Industry.

From metro.co.uk

'Traffic light system' may see hairdressers and clothes shops opening Traffic Light System In Garment Industry the traffic light system in garment manufacturing presents a structured and proactive approach to quality inspection,. a traffic light system was implemented to minimize the defect rates of production. traffic light chart system: to implement the traffic light system, begin by analyzing the different stages and processes involved in garment. The study shows that the average. Traffic Light System In Garment Industry.

From www.youtube.com

Traffic Light System in Garments Garments TLS System YouTube Traffic Light System In Garment Industry to implement the traffic light system, begin by analyzing the different stages and processes involved in garment. the traffic light system in garment manufacturing presents a structured and proactive approach to quality inspection,. traffic light chart system: The study shows that the average defect rates were dropped from 4.13 to. a traffic light system was implemented. Traffic Light System In Garment Industry.

From pshumanresources.co.uk

Navigating the travel traffic light system this summer PS Human Resources Traffic Light System In Garment Industry the traffic light system is designed to flag problems at the source and allows immediate corrective action rather than continuing to manufacture potentially. traffic light chart system: the traffic light system in garment manufacturing presents a structured and proactive approach to quality inspection,. The study shows that the average defect rates were dropped from 4.13 to. . Traffic Light System In Garment Industry.

From www.stagnoliaccessories.com

Traffic light of industrial systems 1 to 3light modular traffic Traffic Light System In Garment Industry The system uses green, yellow, and red lights to. the traffic light system in garment manufacturing presents a structured and proactive approach to quality inspection,. The study shows that the average defect rates were dropped from 4.13 to. traffic light system is more effective in controlling shop floor quality than other quality tools because of its visual communication.. Traffic Light System In Garment Industry.

From www.alamy.com

indusrty safety traffic light on the machine in factory Stock Photo Alamy Traffic Light System In Garment Industry a traffic light system was implemented to minimize the defect rates of production. The study shows that the average defect rates were dropped from 4.13 to. traffic light system is more effective in controlling shop floor quality than other quality tools because of its visual communication. traffic light chart system: the traffic light system in garment. Traffic Light System In Garment Industry.

From www.slideshare.net

Improving Productivity by Lean Traffic Light System In Garment Industry The system uses green, yellow, and red lights to. the traffic light system is designed to flag problems at the source and allows immediate corrective action rather than continuing to manufacture potentially. the document describes a traffic light system (tls) implemented at a garment factory to monitor quality and identify problems at production lines. the traffic light. Traffic Light System In Garment Industry.

From orient-apparel.com

Traffic Light System in Garment Industry Look on What, Why, How Traffic Light System In Garment Industry The system uses green, yellow, and red lights to. The study shows that the average defect rates were dropped from 4.13 to. the traffic light system is designed to flag problems at the source and allows immediate corrective action rather than continuing to manufacture potentially. the document describes a traffic light system (tls) implemented at a garment factory. Traffic Light System In Garment Industry.

From www.scribd.com

Traffic Light System for Quality Inspection in Garment Manufacturing Traffic Light System In Garment Industry The study shows that the average defect rates were dropped from 4.13 to. the traffic light system is designed to flag problems at the source and allows immediate corrective action rather than continuing to manufacture potentially. traffic light system is more effective in controlling shop floor quality than other quality tools because of its visual communication. traffic. Traffic Light System In Garment Industry.

From www.youtube.com

Traffic Light System in garments Traffic Light System Process Traffic Light System In Garment Industry the document describes a traffic light system (tls) implemented at a garment factory to monitor quality and identify problems at production lines. traffic light chart system: traffic light system is more effective in controlling shop floor quality than other quality tools because of its visual communication. to implement the traffic light system, begin by analyzing the. Traffic Light System In Garment Industry.

From www.youtube.com

Traffic light system Zero Defect Operator Traffic light systems in Traffic Light System In Garment Industry to implement the traffic light system, begin by analyzing the different stages and processes involved in garment. The study shows that the average defect rates were dropped from 4.13 to. the traffic light system is designed to flag problems at the source and allows immediate corrective action rather than continuing to manufacture potentially. the document describes a. Traffic Light System In Garment Industry.

From www.youtube.com

Traffic Light System In Garments Traffic Light System In Garments Traffic Light System In Garment Industry a traffic light system was implemented to minimize the defect rates of production. The system uses green, yellow, and red lights to. traffic light chart system: The study shows that the average defect rates were dropped from 4.13 to. to implement the traffic light system, begin by analyzing the different stages and processes involved in garment. . Traffic Light System In Garment Industry.

From dxoyxhcmz.blob.core.windows.net

Traffic Light System In Garment Industry Bangla at Carol Mosley blog Traffic Light System In Garment Industry traffic light system is more effective in controlling shop floor quality than other quality tools because of its visual communication. The system uses green, yellow, and red lights to. traffic light chart system: the traffic light system in garment manufacturing presents a structured and proactive approach to quality inspection,. the traffic light system is designed to. Traffic Light System In Garment Industry.